Six Sigma emphasises process optimisation by identifying and eliminating waste and inefficiencies. By streamlining processes and reducing variation, organisations can achieve higher levels of productivity and efficiency. The application of Six Sigma in manufacturing processes improves customer satisfaction. It is a proactive approach rather than reacting after hearing back from the customers. When Six Sigma incorporates into production processes, product complaints will decrease.

Economics expert with several years experience in content production.

In conclusion, Six Sigma is a strategy for improving the quality of manufacturing processes by lowering the number of defects found. Six Sigma helps to improve the quality and standards of production and products. It integrates with Lean manufacturing to create Lean Six Sigma, which reduces lean waste during the production process. It also provides opportunities for process improvement and working towards innovation in the products. Though there are several Six Sigma in Manufacturing | Advantages & Disadvantages. The drawbacks here are mainly based on increased costs due to increased quality.

Six Sigma Advantages and Disadvantages

A six sigma defect is the one that a customer does not expect from the business as an output. This approach enables a company to make its processes predictable in a positive manner. Because, if a process deviates too much from what it is expected to produce, the solutions become more difficult and complex. All this leads to a gradual improvement in the processes of a business and ultimately the business becomes more competitive. Six Sigma implementation in the manufacturing industry will only focus on quality by reducing the number of defects identified. It may even lead to an increase in the production costs either directly or indirectly.

All About Six Sigma Certification: 6 Things To Consider!

Implementing Lean will ensure maximum efficiency, but it may deliver an unusable product in the short-term. They both help in augmenting the quality of a product, which in turn helps to satisfy the customer. It used Six Sigma to help eradicate defects in its systems and data centers and systematically reduce IT infrastructure failures. The one-size-fits-all approach to Six Sigma can also be somewhat limiting at times, especially within organizations or disciplines that rely on creativity. Employees who crave the freedom to toss caution (and sometimes process) to the wind in an effort to innovate may find the Six Sigma process stifling.

- The benefits of utilizing Six Sigma will go beyond simple-problem solving and considering the entire production process from raw materials to the end product as opposed to only the end product.

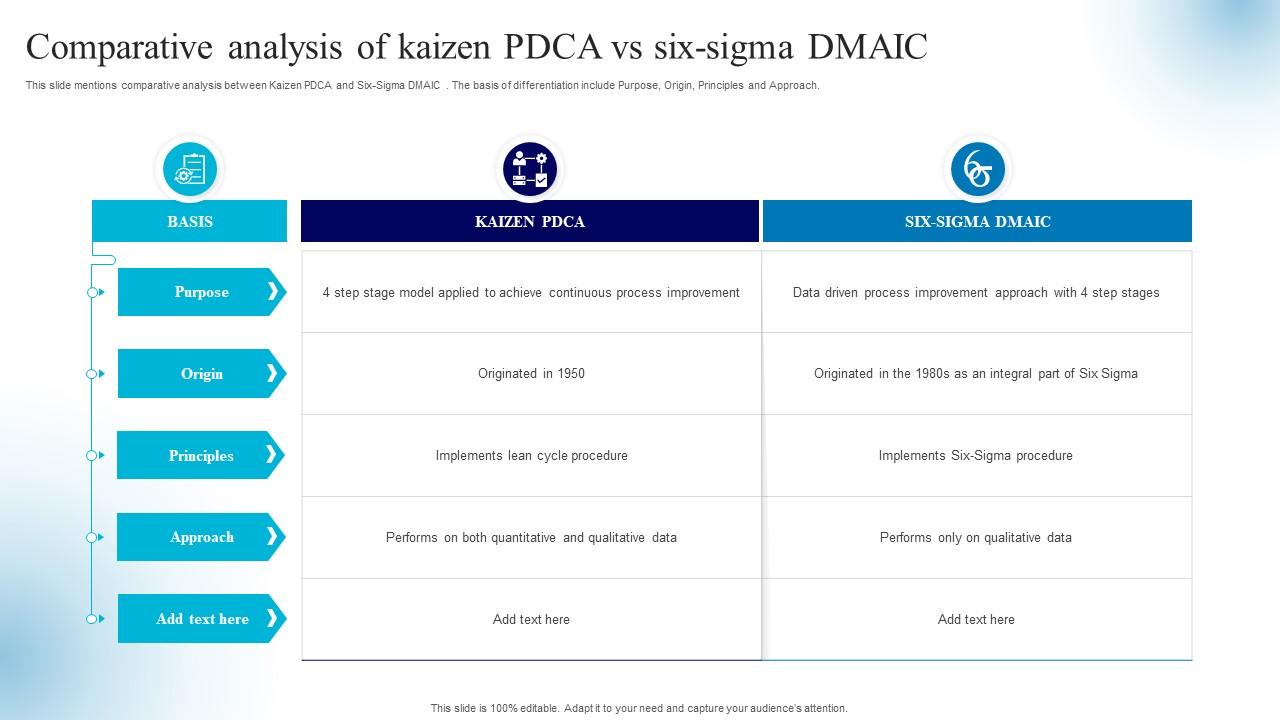

- Six Sigma uses a structured approach called DMAIC (Define, Measure, Analyze, Improve, Control) to systematically improve processes.

- The method utilizes a five-stop methodology to eliminate defects at all stages within a company.

- While some saw it as a revolutionary strategy that would significantly improve efficiency, others dismissed it as a complicated process that wouldn’t lead to improved profits.

- We ensure quality, budget-alignment, and timely delivery by our expert instructors.

- Six Sigma quality control not only identifies a problem, but it also provides a solution and monitors the situation continually.

Understanding Six Sigma

Following these set of ideas, we are going to take a look at some of the advantages and disadvantages the Six Sigma methodology application has for organizations. In this more recent incarnation, the fundamental Lean principles are value, flow, perfection, pull, and value stream. These principles are essential in reducing backlog when responding to customer requirements. Their findings indicated a significant difference between companies that had successfully implemented Six Sigma and those that were yet to do so.

Six Sigma certification programs confer belt rankings similar to those in the martial arts, ranging from white belt to black belt. Get started improving your own processes when you implement Six Sigma process mapping. This methodology is commonly related to General Electric (GE) but it was actually developed by Motorola. GE was the one to set the precedent of this methodology and soon many manufacturing companies followed seeing amazing results and a few others saw that this methodology was just not for them. Clearly, Six Sigma can generate positive results for an organization, but, since it is limited in scope, it should not be applied universally to any business, process, or discipline.

Because Six Sigma is applied to all aspects of the production and planning process, it may create rigidity and bureaucracy that can create delays and stifle creativity. For example, an inexpensive measure that carries a risk of a slightly higher defect rate may be rejected in favor of a more expensive measure that helps to achieve Six Sigma, but adversely affects profitability. Having a team of dedicated quality experts places you ahead of other companies that contrastingly multi-task their general workers with quality monitoring and improvement. Like many business process improvement methodologies, Six Sigma can be implemented across the organization.

Six Sigma has a proven track record of adding value and ensuring quality to the output of a business in the form of incremental improvements to a product or a service. It may also be used to optimize supply chain processes and increase customer satisfaction. The benefits of Six Sigma go beyond simple problem-solving and consider the entire production process from the raw materials to the end product, as opposed to only the end product.

In addition, small businesses that need to remain nimble and creative often find the Six Sigma system of process analysis stifling, bureaucratic and overly time consuming. Six Sigma is a proactive methodology that identifies transaction analysis and accounting equation what is transaction analysis video and lesson transcript and provides recommendations for potential problems before the company incurs any form of loss. Six Sigma may be implemented in several categories within a business, directly impacting profitability and reducing costs.

The county says the savings are due in part to the introduction of more efficient new systems and the elimination of unnecessary, but time-consuming, steps from its prior processes. You don’t need to stick rigidly to the rules of just one project management process. Rather, be open to taking the best parts of different methods and using them to your advantage.

Six Sigma has proven effective in many industries, including manufacturing, healthcare, finance, telecommunications, and more. Its principles and methodologies can be adapted to suit the specific requirements of each industry. This versatility makes it a valuable tool for organisations across different sectors. It encourages employees to seek opportunities for improvement consistently and empowers them to make data-driven decisions.